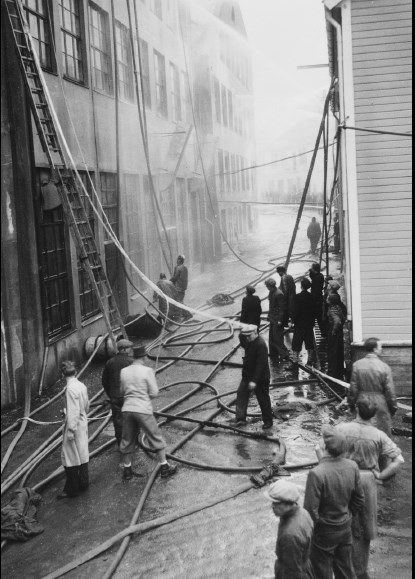

It was early morning on the 30th March 1950 when disaster struck: Devoldfabrikken was on fire! A factory on fire is a tragedy affecting many, but what actually happened that fateful day?

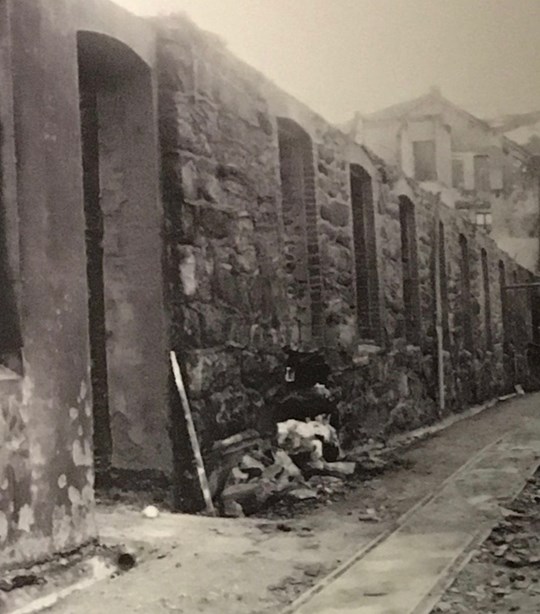

This huge fire started when flames first took hold of the drying machine in the old main building at Devoldfabrikken. Witnesses described it as an explosion setting the entire building alight. The fire immediately spread across the street to the wool blending department that burned down to the ground. The third floor of the dye works also caught fire, but luckily the firefighters managed to extinguish this quickly.

Both the firefighters from Devoldfabrikken’s own fire prevention unit and the local fire protection unit in Langevåg, with assistance from Ålesund and Spjelkavik, made a huge effort and managed to prevent the entire factory burning down.

After the fire 220 of Devoldfabrikken’s employees were left unemployed, but luckily, they were back at work after just a couple of months. Production started up again relatively quickly with a carding machine and four spinning machines in the shoddy mill* (textile recycling mill). The weaving and sock department had only suffered minor damage and was fortunately able to start up again promptly, while the knitwear department managed to restart production as soon as the power was restored to the mill. Some work was outsourced to other factories for a short period in order to prevent customers being affected by the situation.

With strong growth in production after World War II and 773 employees, it was important to rebuild the factory as soon as possible. The new main building had a floor area of 6000 square meters with a full basement and two floors, as well as a third floor in the middle part.

*pre 1850’s these where known in English as “shoddy mills” until the word shoddy degenerated to mean bad workmanship from the late 1800’s until the present day. At that time the word shoddy was only used as the name of a type of woollen yarn produced by tearing old woollen rags into shreds and weaving the strands, sometimes with the addition of some new wool, to make a cloth, also known as shoddy. Shoddy is still used in the Norwegian language to describe this product.